Prisma® Variety Pack Systems

Variety Pack Solutions Your Way

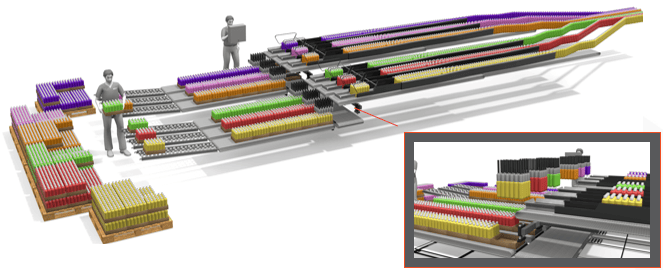

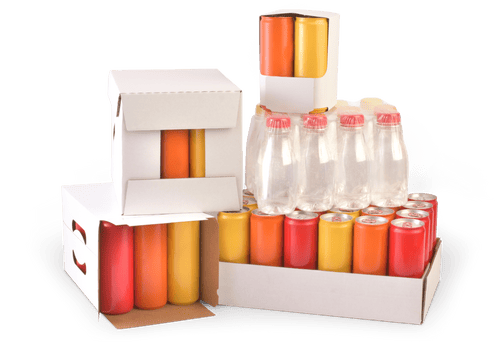

Available in multiple configurations to package your variety offerings efficiently and reliably, Prisma systems utilize class-leading technology platforms with gentle product handling throughout the process. From simple systems with manual load infeeds to fully automated systems with high speed continuous motion packers, we integrate proven technologies in the ideal configuration for your application. Prisma systems fully integrate three key elements for producing variety packs. These elements include the unloading and delivery of product flavors, the routing of empty supply trays and the final packaging of the variety pack. Designed for your dynamic marketing needs with the unparalleled performance, reliability and support you expect from the leader in customer driven packaging solutions.- Cartons – Production capacity and variety pack flexibility to fuel your product’s growth

- Shrink Bundles – Help your product sell itself with attractive variety shrink packs

- Cases & Trays – Offering product protection and brand enhancing graphics

- Prisma manual unload stations: Enables personnel to manually unload flavor varieties, delivering product to flavor lanes that feed packaging equipment.

- Prisma automated unloaders: Receives multiple lanes of supply product trays, unloads and delivers product to flavor lanes that feed packaging equipment.

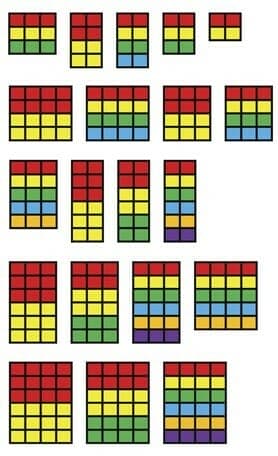

- Multiple variety pack system configurations available

- Flavor unloading and delivery

- Product unloading tailored to application needs

- High throughput cartoning and shrink packing

- Flexible intermittent motion cartoning and casing

- Supply tray routing and repacking

- Prisma manual unload stations: Enables personnel to manually unload flavor varieties, delivering product to flavor lanes that feed packaging equipment

- Prisma automated unloaders: Receives multiple lanes of supply product trays, unloads and delivers product to flavor lanes that feed packaging equipment

- Empty tray discharge from the Prisma automated unloaders

- Routing of empty supply trays to downstream packaging equipment for repacking with product varieties

- Empty trays are routed for recycling or other uses if not being repacked

Specifications

| Product Types: | Beverage cans – standard, sleek, slim and larger volume cans Food cans PET bottles – semi-rigid round bottles |

| System Flavor Unloading: | From 2 to 8 flavors delivered to the packaging machine infeed Up to 6 manual unload stations Up to 8 automated unloader supply lanes |

| System Retail Packaging: | Capable of producing 4, 6, 8, 9, 10, 12 (2×6), 12 (3×4), 15, 16, 18, 20, 24, 28, 30, 32 and 35 count packages depending on system configuration Cartoning speeds ranging from 25 to 125 cartons per minute Shrink packaging optimized for speeds of 30, 60 or 80 packs per minute Case & Tray packing with intermittent and continuous motion machines covering speed below 40 and up to 80 cases per minute |

Final packaging

Cartons

Production capacity and flexibility to fuel product growth

Cartons

Production capacity and flexibility to fuel product growth

Cartons

Production capacity and flexibility to fuel product growth

Cartons

Production capacity and flexibility to fuel product growth

- Select automation level based on production goals and budget

- Moderate speed economical solutions

- Intermittent motion cartoning up to 40 cpm

- Optional pack pattern rotation expands flavor count capability

- Maximize production with continuous motion cartoning solutions with speeds up to 125 cpm

- Menu driven product selection simplifies changeovers

- The perfect combination of product visibility, package integrity and convenience

- Shrink bundling with or without support pads and trays (new or reloaded supply trays)

- Ease of operation and changeover and low package costs

- Meets production needs from 20 to 100 retail packs per minute

- Excellent product and packaging material control provides high efficiency and enhances brand with exceptional package quality

- Intermittent motion case packing up to 40 cpm

- High throughput continuous motion case packing up to 80 variety pack cases per minute

- Tray packing options include the repacking of flavor supply trays, saving material costs

The Prisma® unloader can be combined with a variety of systems to automate product infeed. It is available for cans, bottles or both and automatically unloads trays and conveys them for downstream packing.

Explore Variety Pack options »