Case & Tray Packer

Unprecedented Efficiency and Economy

Conveniently flexible and loaded with experience-based design, Invex® IM case and tray packers bring a higher level of performance to mid-range applications. Its simplistic combination of design, positive drive technology and control avoids compromise and maximizes performance.- Speeds up to 25 cases or trays per minute

- A variety of infeeds and metering techniques for efficient product handling

- Touch screen selectable product recipes automatically control precise adjustments throughout the machine

- Simple and repeatable changeovers

- Sanitary frame design and stainless steel washdown options

Fast, repeatable changeover feature offers multiple enhancements.

Changeover time – significantly reduces time to less than 5 minutes (time of changeover is dependent on extent of changeover)

Repeatability – rail positions are recipe-driven and locked in place to within +/- 1/32″

Flexibility – ability to place lanes where desired as opposed to centerline or fixed side adjustments and more customer options for generating product-specific recipes

Durability – infeed rail’s holding force can withstand high product pressure

Ergonomics – minimizing manual adjustments maximizes efficiency and promotes safety in the work environment

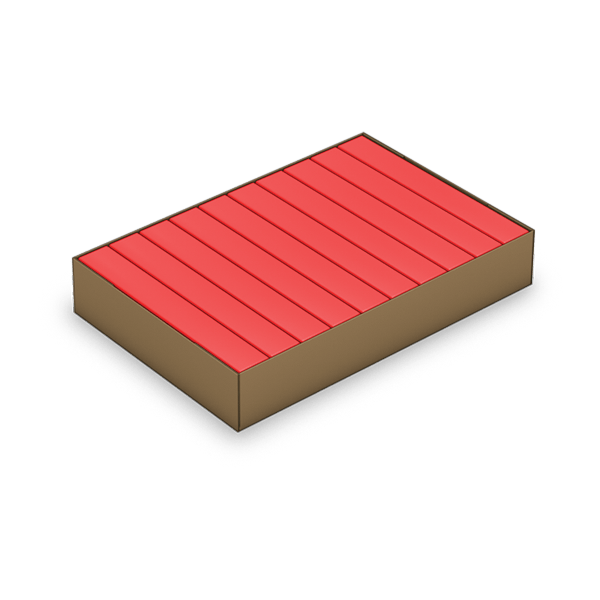

Innovative collating and loading technology that fits your application needs. Offering maximum flexibility and adaptability for rapidly changing product life cycles, the Invex IM performs to meet production demands.

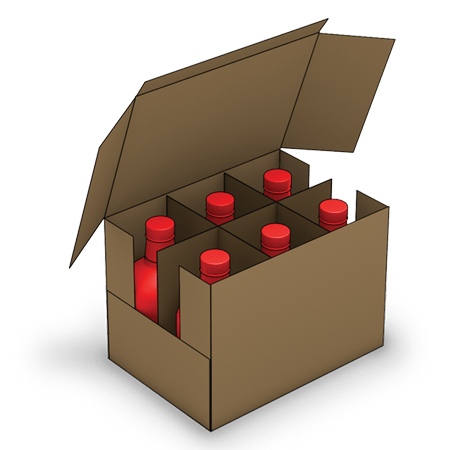

Stage Push – A horizontal collation process used for handling cartons when vertical stacking is not required.

Pick and Place – Ideal for products such as tapered cups that cannot be pushed one against the other. A variety of vacuum or mechanical techniques are used, depending on the application.

Up Stacker, Down Stacker – An easy and cost effective method of vertically stacking cartons at lower case rates.

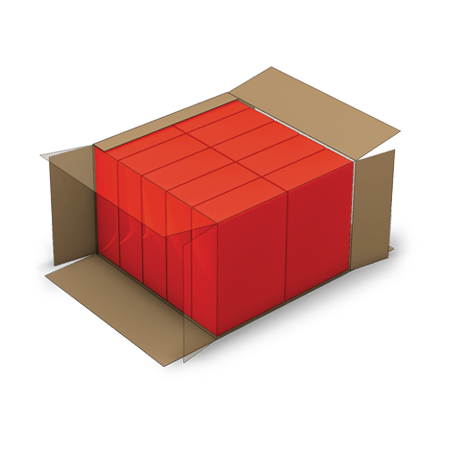

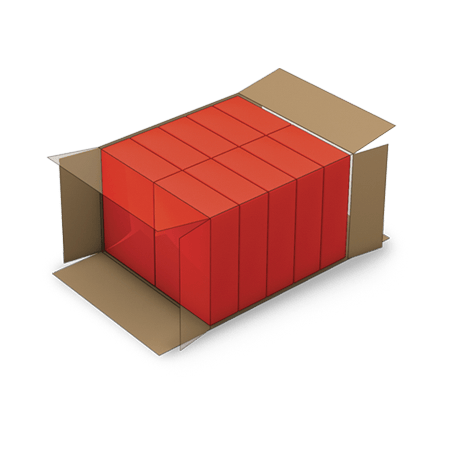

Intelligent, precise case blank and product control during the loading process ensures consistent, reliable production.

Precisely automated servo control ensures case blank and product loading are executed consistently and reliably for your full range of pack patterns, products and speeds. From case flap folding, to squaring, to compression and gluing, critical operations are precisely automated according to your pre-set recipes, ensuring more efficient, reliable production and faster, easier changeovers.

Case and Tray Blank Control – A main contributor to increased efficiency and speed is the ability to control and fold case and tray blanks. The Invex® IM avoids the use of air cylinders that can bind or degrade over time resulting in variable timing, velocity and position. Its positive servo driven drive system precisely controls case setup, case flap control, the funneling of product during loading, case flap tucking and folding (no plows), case squaring and the compression and sealing of flaps.

Case Squaring – Four corner case control squares the leading and trailing walls of the case just prior to case sealing and compression. Positive control of the case squaring guarantees a quality package.

Specifications

| Invex IM 24″ (609.6 mm) (Index) | Invex IM 30″ (762 mm) (Index) | |

|---|---|---|

| Speeds: | Up to 25 cases/minute typical (application dependent) | Up to 20 cases/minute typical (application dependent) |

| Case Types: | Wraparound cases, knockdown cases (pre-glued manufacturer’s flap) and trays RSC, HSC or economy flaps Minimum: 2″ (50.8 mm) Maximum: 6″ (152.4 mm) | Knockdown cases (pre-glued manufacturer’s flap) and trays RSC, HSC or economy flaps Minimum: 2″ (50.8 mm) Maximum: 6″ (152.4 mm) |

| Case Size Range: | Minimum: 4″ (101.6 mm) x 6″ (152.4 mm) x 4″ (101.6 mm) Maximum: 16″ (406.4 mm) x 22″ (558.8 mm) x 12″ (304.8 mm) *Direction of Travel x Vertical x Across Machine | Minimum: 8″ (203.2 mm) x 8″ (203.2 mm) x 4″ (101.6 mm) Maximum: 23″ (584.2 mm) x 22″ (558.8 mm) x 16″ (406.4 mm) *Direction of Travel x Vertical x Across Machine |

| Frame/Finish: | Powder coated tubular and fabricated cold rolled steel Gray metallic, DuPont 616 Washdown options available | Powder coated tubular and fabricated cold rolled steel Gray metallic, DuPont 616 |

| Magazine Capacity: | 4′ (1219.2 mm) magazine, 6′ (1828.8 mm) optional | 4′ (1219.2 mm) magazine, 6′ (1828.8 mm) optional |

| Glue System: | Nordson ProBlue® | Nordson ProBlue® |

| Adjustments: | HMI selectable recipes, threaded screws, handwheels and hand knobs with position pointers and digital scales | HMI selectable recipes, threaded screws, handwheels and hand knobs with position pointers and digital scales |

| Guarding: | Category 3 guarding Full length polycarbonate with extruded anodized aluminum frames | Category 3 guarding Full length polycarbonate with extruded anodized aluminum frames |

| Electrical: | Rockwell Automation (AB) programmable logic controller, servo motors, drives and PanelView+ HMI NEMA 12 wiring and enclosures Washdown (optional) | Rockwell Automation (AB) programmable logic controller, servo motors, drives and PanelView+ HMI NEMA 12 wiring and enclosures Washdown (optional) |

| Power: | 480V, 50/60HZ, 3PH Second 480V drop down for glue unit Other power sources available | 480V, 50/60HZ, 3PH Second 480V drop down for glue unit Other power sources available |

| Air: | 90 PSI (6.2 bar) | 90 PSI (6.2 bar) |

Invex® IM case and tray packers easily accommodate large size ranges and pack patterns for food, beverage and more.